Home | Uncategorized |

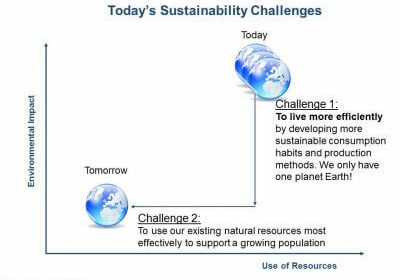

Building for Tomorrow: Less material, Less Energy, Increasing Recycling/Recovery and Responsible Sourcing

The Alu foil industry has already significantly reduced the environmental impact of the aluminium foil used today and continues to initiate new and innovative ways to make alufoil even more sustainable.

Light Weight

Using thinner gauge aluminium foil to deliver the same functionality saves both the aluminium and the energy needed to produce it. Over the last decade, the European foil industry has improved production processes so that the gauge of foil used in packaging and other applications has reduced by 10-20%. Whilst there will be a practical limit to which the foil thickness can be further reduced, the industry is still predicting another 10% reduction in the coming 10 year period.

Less Energy, Less Scrap

In the period 2005-2010, the aluminium foil producers in Europe reduced the energy they used by over 30%.

Increasing Foil Collection, Recycling & Recovery Rates

Increasing collection and recycling/recovery rates for aluminium foil and alufoil packaging means that an equivalent quantity of primary (i.e. virgin) aluminium will not be required by the industry. This represents a significant energy saving as processing recycled aluminium requires 95% less energy than the equivalent quantity of primary metal produced from bauxite.

Strongly supported by the industry, foil container collection rates have steadily increased throughout Europe with the reported average collection rate of above 50% for 2010. An additional, but as yet unquantified, quantity of aluminium (packaging) is also recovered from the waste to energy incineration plant bottom ashes.

The full article can be found at alufoil.org.